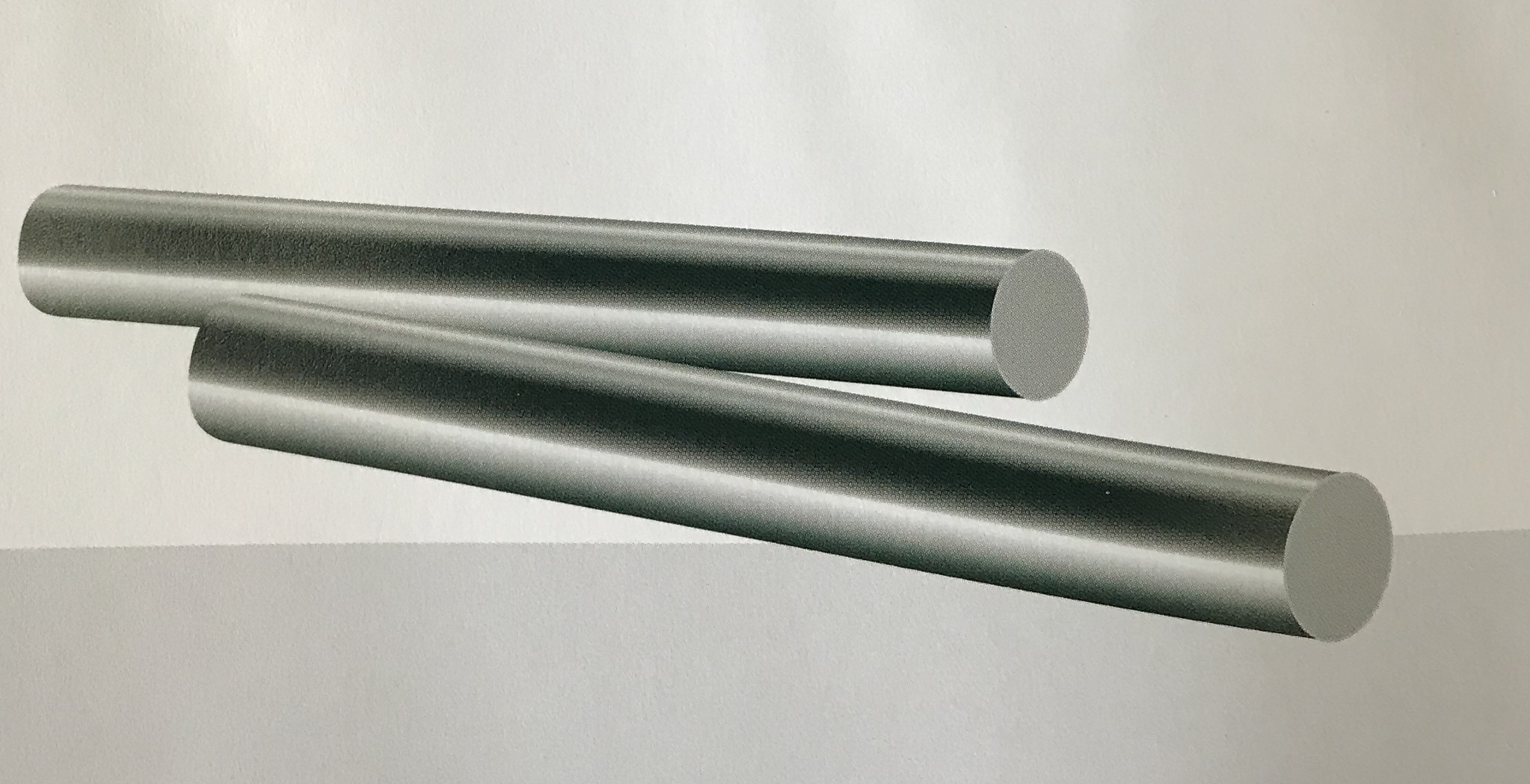

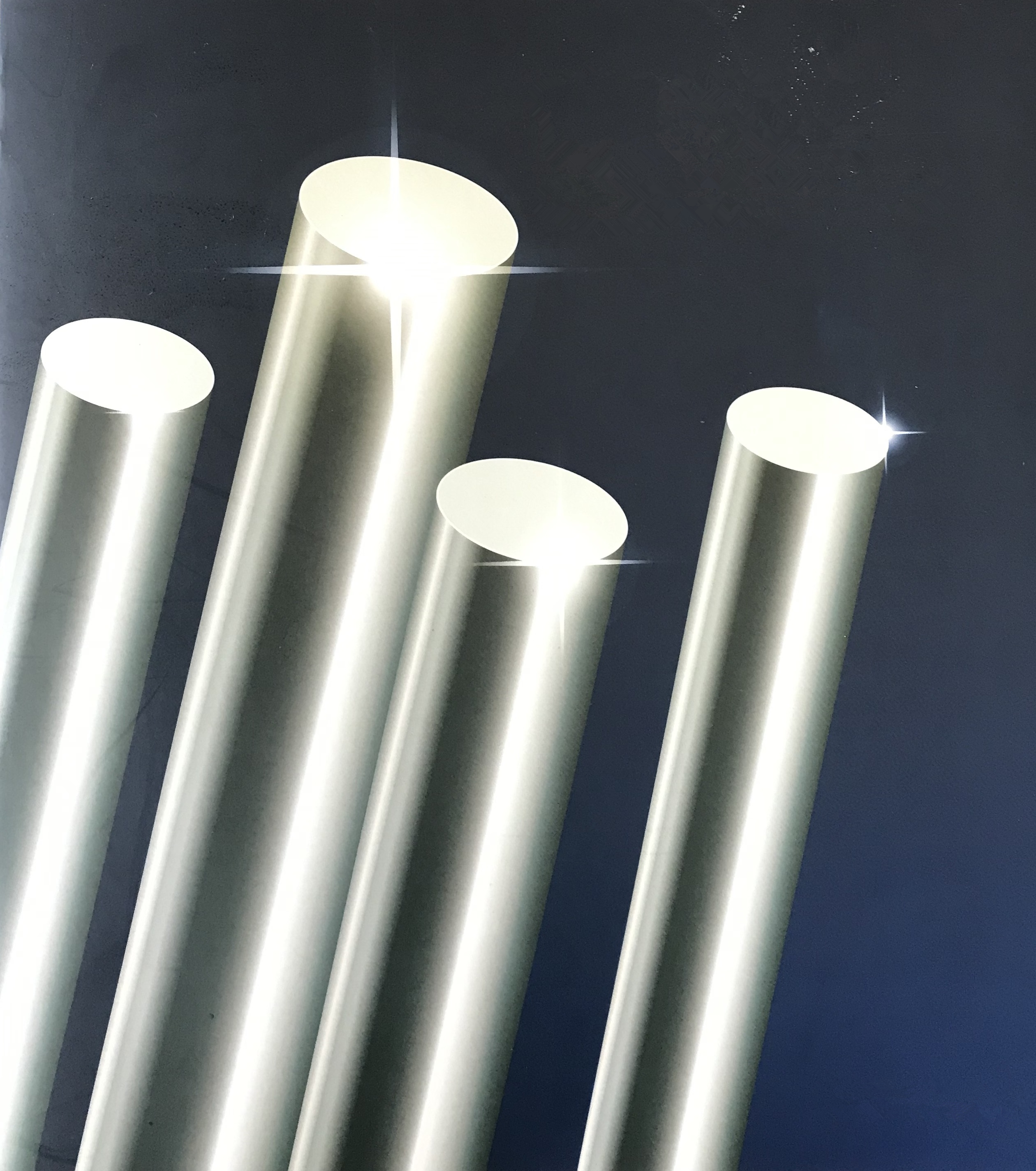

HIGH SPEED STEEL ROUND BAR(Co)

高速工具圆钢/钴高速工具圆钢

HIGREAT作为全球高速工具钢材料领域的最佳设计者,一直引领着全球高速钢刀具的应用,HIGREAT的成长与发展离不开全球客户对我们的支持与帮助,同样,我们用高品质的产品,帮助我们的客户创造出更多的价值,为客户提升市场竟争力。

HIGREAT as the world's best designers in the field of high speed tool steel materials, has been leading the global application of high speed steel cutter, growth and development of HIGREAT with the global customer support and help , also, we use high quality products and help our customers create more value, improving market competitive force.

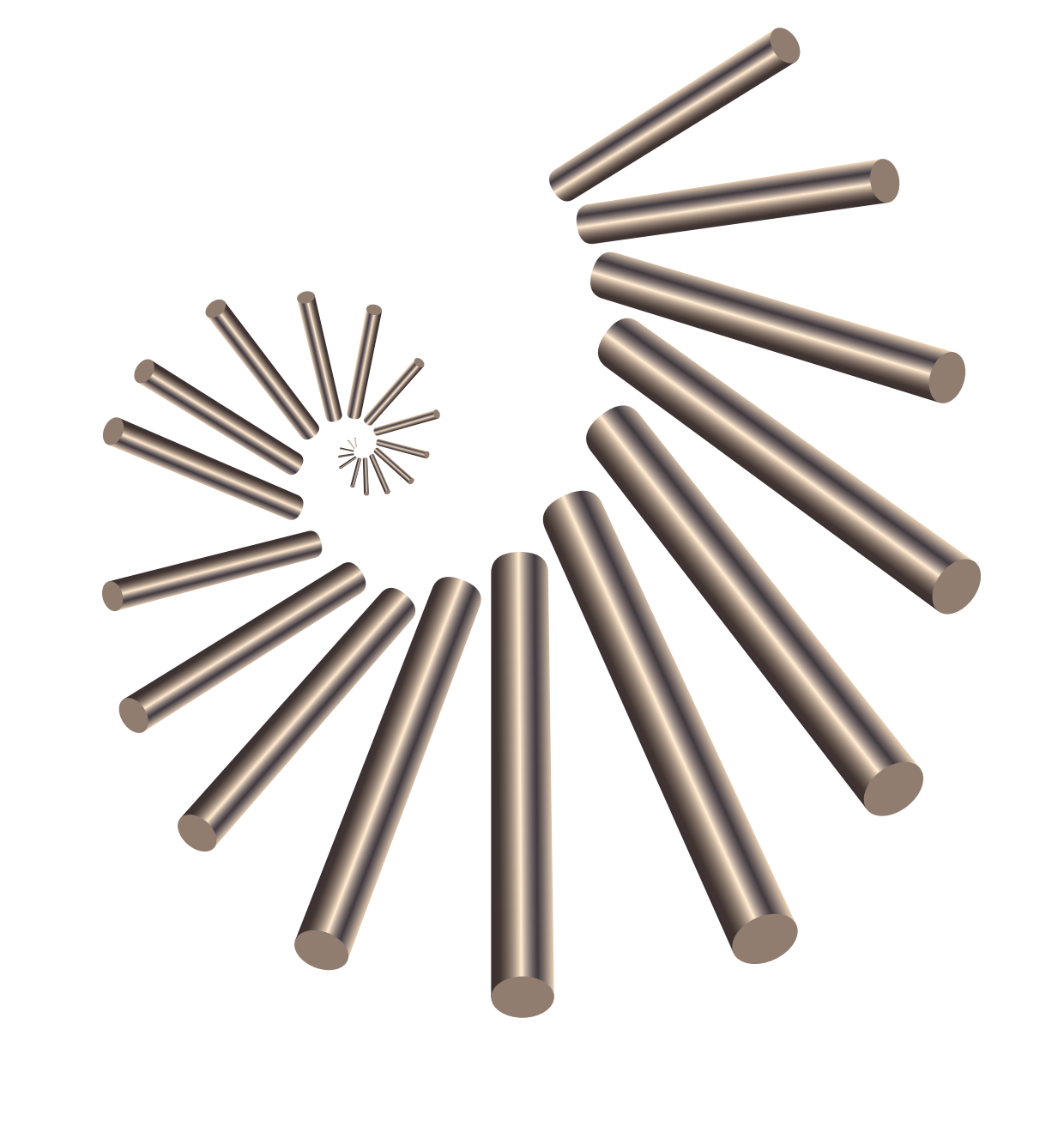

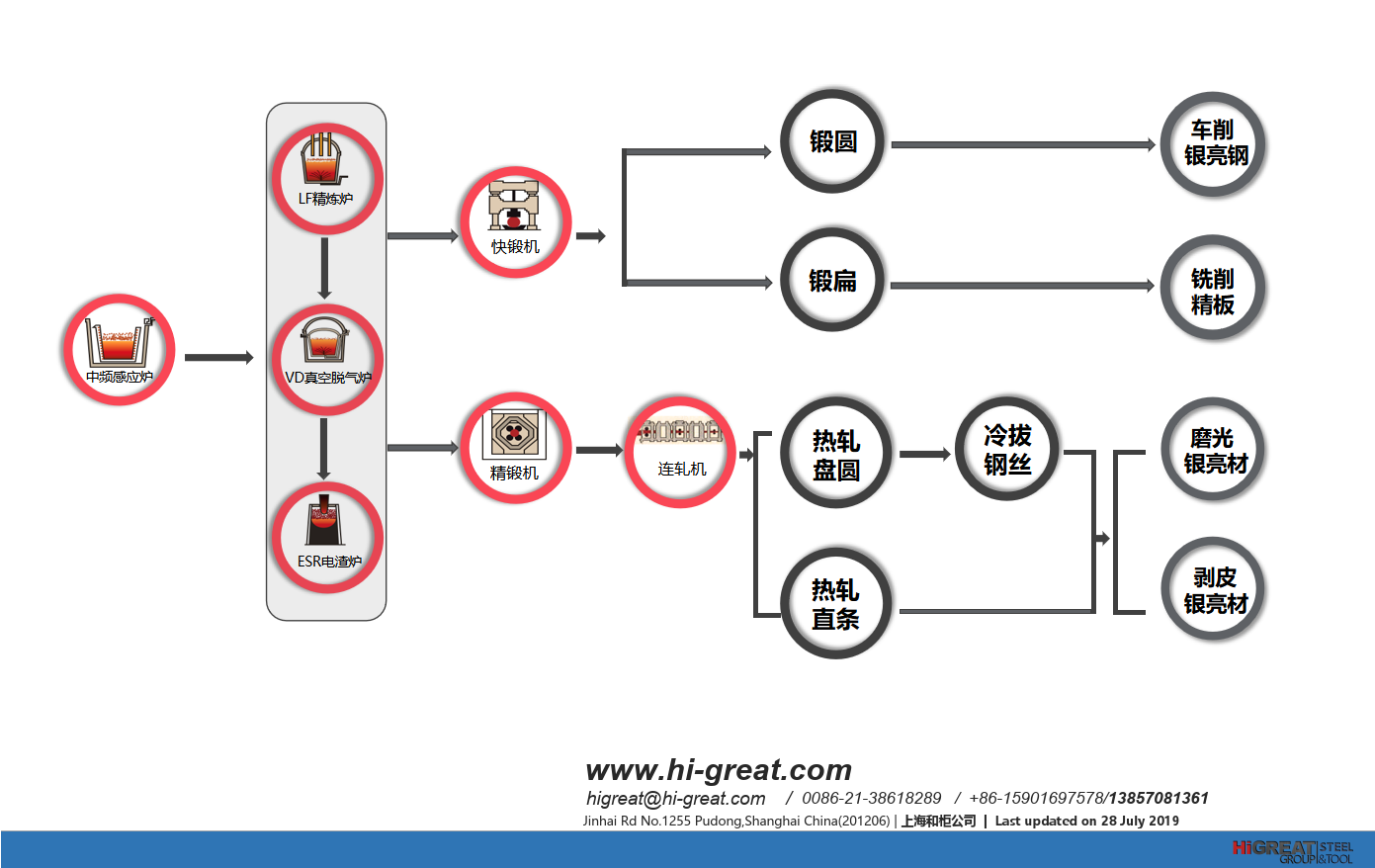

6类供货产品及全规格范围覆盖,满足客户所有材料应用场景 Size Range

HIGREAT可为客户提供高速钢电渣锭、锻制圆钢、锻制模板、热轧盘圆、热轧直条、冷拔钢丝6种产品。

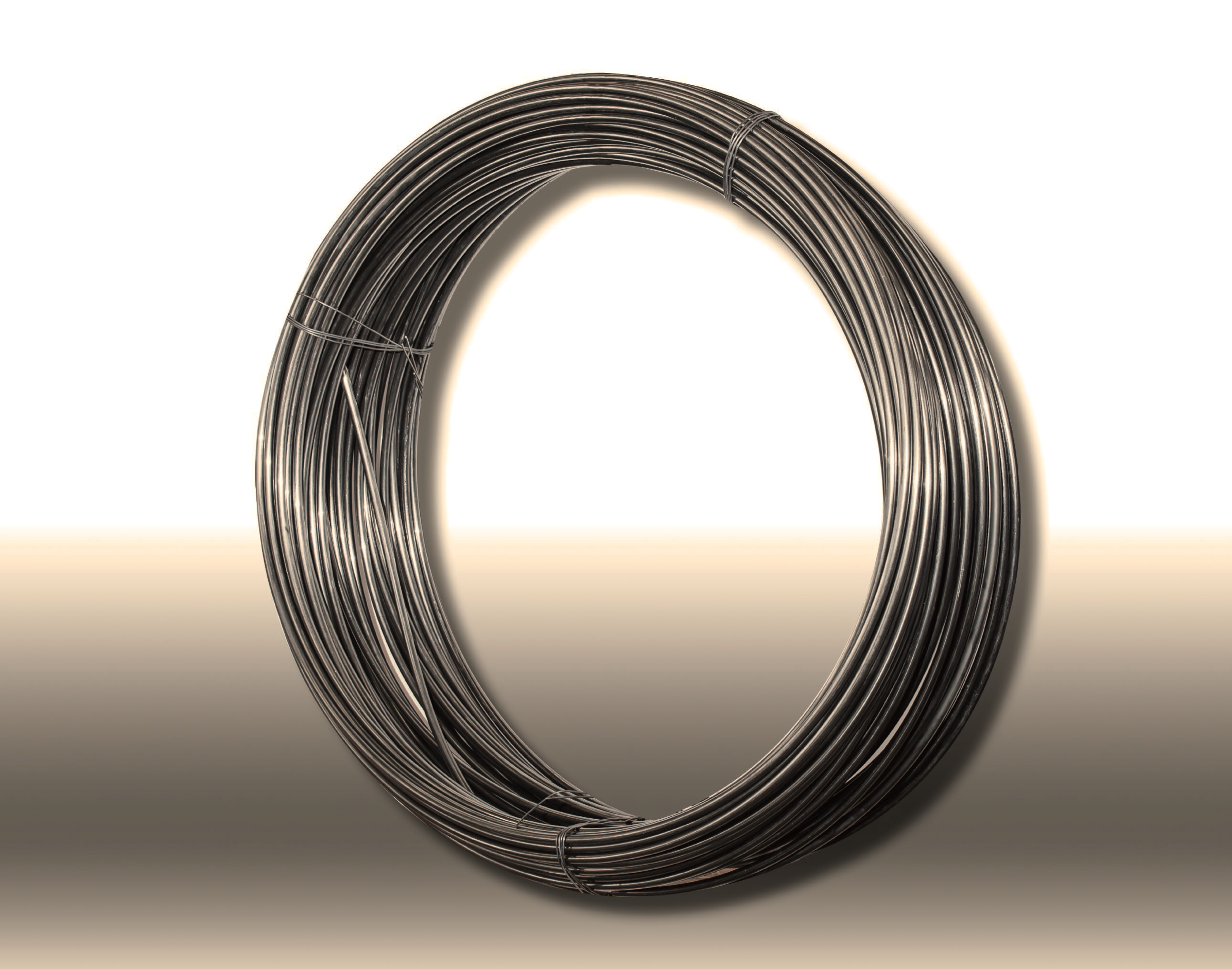

拉丝系列规格主要范围为2mm~15mm

热轧材系列规格主要范围为16mm~55mm

锻材系列规格主要范围为56mm~150mm

...

各系列同时提供银亮材,详情见附表

Cold draw: dia.2mm~15mm

Hot rolled : dia.16mm~55mm

Forging size: dia.56mm~150mm

品质稳坚如磐石,信任始终如一 High quality with consist trust from customers

HIGREAT经过17年的不懈努力,其代工生产基地现已发展成为全球高速工具行业产业链条最完整、规模最大、装备最先进、市场份额最大,同时拥有众多国际知名品牌及专利技术的跨国性刀具集团,覆盖了从原料猎取到生产制造到分销服务,直至资源循环利用的所有关键环节。

材料设计及生产制造,作为整个高速钢产业键条中极为重要的一环,采用与世界先进水平保持同步的生产及检测设备,可提供高速工具钢、模具钢钢材,产品种类覆盖锻材、热轧材、冷拔材以及各种银亮材系列。

秉承17年的高速钢刀具生产历史与经验,HIGREAT用高品质的产品帮助我们的客户创造更多的价值。

高标准、高质量

使用先进的生产设备,独特的精炼工艺,高于中国国家标准的工艺要求,生产出高纯度、高质量的钢材。

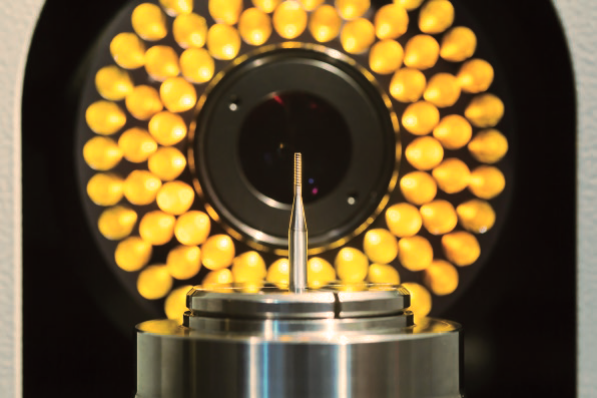

始终如一的质量保障体系

通过国际领先的检测设备,遵照ISO9001国际质量管理体系,从材料设计到生产制造,对各环节的各道工序进行严格的质量管理,保证交货产品质量满足客户订单要求。

专业及经验积累丰富

HIGREAT在高速钢刀具生产方面拥有17年的历史,凭借优秀的产品质量、丰富的市场经验及市场美誉度,保持快速增长,超过1500多次出口经验,HIGREAT对客户的需求和市场把握方面,我们能提前想客户所想,供客户未来期望的高速工具钢刀具材料。

持续改进与升级

通过聘请海内外客座专家,建立核心技术研发团队,并与高校展开产学研合作方式,持续改进生产工艺,对钢材材料进行升级,与客户分享我们的研发成果。

With 17years efforts,HIGREAT’s production base has grown to become the world's high-speed tool industry with most complete industry chain, the largest and the most advanced equipment, the biggest market share. at the same time with many international famous brand and patent technology of transnational tool group, covering the organization from raw material to the production and manufacturing to distribution services, until the resource recycling of all key link.

Material design and manufacturing, as a very important link in the whole high-speed steel industry, with the production and testing equipment keeping pace with the world's advanced level, can provide high-speed tool steel, mould steel, product categories covering forging, hot rolled, cold drawn and a variety of bright bars.

With 17 years of high speed steel cutting tool production history and experience, HIGREAT helps our customers create more value with high quality products.

High standard, high quality

Using advanced production equipment, unique refining process, higher than China's national standards for the production of high purity, high quality steel.

Consistent quality assurance system

Through the international leading testing equipment, in accordance with the ISO9001 international quality management system, from material design to manufacturing, strict quality management of each step of the process, to ensure that the quality of products delivered to meet customer order requirements.

Professional and rich experience accumulation

HIGREAT produced in high speed steel cutter has 17 years of history, with excellent product quality, rich market experience and market reputation, maintain rapid growth, more than 1500 export experience for many times, HIGREAT grasp of customer needs and market aspect, we can want to customers think in advance, for customer's expectations of future high speed tool steel cutting tool materials.

Continuous improvement and upgrading

By hiring domestic and overseas guest experts, establish the core technology research and development team, and carry out industry-university-research cooperation with universities, continuously improve the production process, upgrade steel materials, and share our research and development results with customers.

最佳设计Leading desigen

由设计领先至工艺领先和设备领先

Leading from design to technology and equipment

从材料设计源头一开始就保持领先

Stay ahead from the beginning of material design

HIGREAT作为材料领域的设计标杆,我们始终坚持材料设计研发领先原则, 我们从设计领先开始,再到生产设备领先和工艺领先,三个领先有续协作,帮助客户提升竟争力。

As a design benchmark in the field of materials, HIGREAT always adheres to the principle of leading in material design and development. And continue to integrate all resources to help customers improve their competitiveness.

图示说明Pictures specifications:

![]() 1 SX-35精锻机,设备投入2亿,600吨精锻机,锻造钢锭最大直径240mm,重量360KG,可生产Φ80mm~Φ150mm成品锻圆

1 SX-35精锻机,设备投入2亿,600吨精锻机,锻造钢锭最大直径240mm,重量360KG,可生产Φ80mm~Φ150mm成品锻圆

![]() 2 SMX精锻,设备投入1.2亿,180吨精锻机,锻造钢锭最大直径190mm,重量200KG,可生产Φ55mm~Φ80mm成品锻圆

2 SMX精锻,设备投入1.2亿,180吨精锻机,锻造钢锭最大直径190mm,重量200KG,可生产Φ55mm~Φ80mm成品锻圆

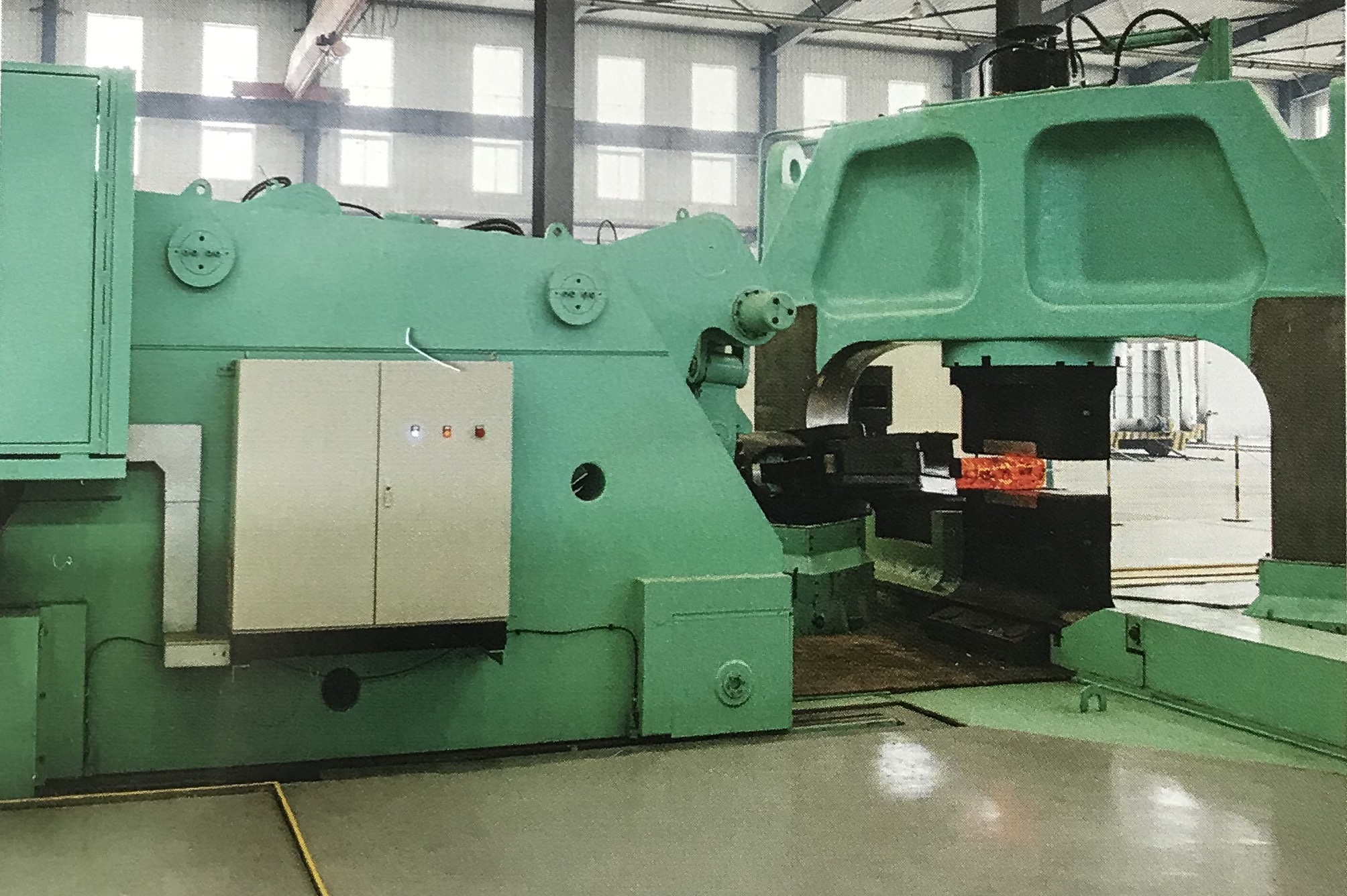

![]() 3 棒线材连轧机,设备投入8200万,Φ450横列式轧钢机3架,平立交替连轧机14架,顶角45度摩根轧机6架,可提供Φ16~Φ55热轧真条,以及Φ5.5mm~Φ15mm热轧盘圆

3 棒线材连轧机,设备投入8200万,Φ450横列式轧钢机3架,平立交替连轧机14架,顶角45度摩根轧机6架,可提供Φ16~Φ55热轧真条,以及Φ5.5mm~Φ15mm热轧盘圆

![]() 4 1600T液压快锻机组,设备投入2000万,可锻造钢锭重量0.5T~3T;锻圆直径Φ100~Φ200mm;扁坯、模块厚度60mm~150mm*宽度200mm~350mm

4 1600T液压快锻机组,设备投入2000万,可锻造钢锭重量0.5T~3T;锻圆直径Φ100~Φ200mm;扁坯、模块厚度60mm~150mm*宽度200mm~350mm

5 ESR,32台

6 连轧操控室

7 退火中心

8 磨光作业

9 预热工序

10 锻坯工序

11 精锻工序

12 精锻操控室

1-SX-35 Precision forging machine,for round dia.Φ80mm~Φ150mm

2-SMX forging machine,for round dia.55mm~Φ80mm

3-Continuous rolling mill. For round Φ16~Φ55,and wire Φ5.5mm~Φ15mm

4-1600T Hydraulic forging machine.for round Φ100~Φ200mm or flat block size 60mm~150mm*200mm~350mm

5-32 sets of ESR furnace

6-Control room for continuous rolling mill

7-Annealing center

8-Grinding machine

9-Heating furnace

10-Forging raw material

11-Precision forging

12-Control room for precision forging mill

注:图1至图4设备投入约4.2亿CNY,约6000多万USD

高速钢用途 PURPOSE OF HIGH SPEED STEEL

高速钢牌号及化学成份 STEEL GRADE AND CHEMISTRY

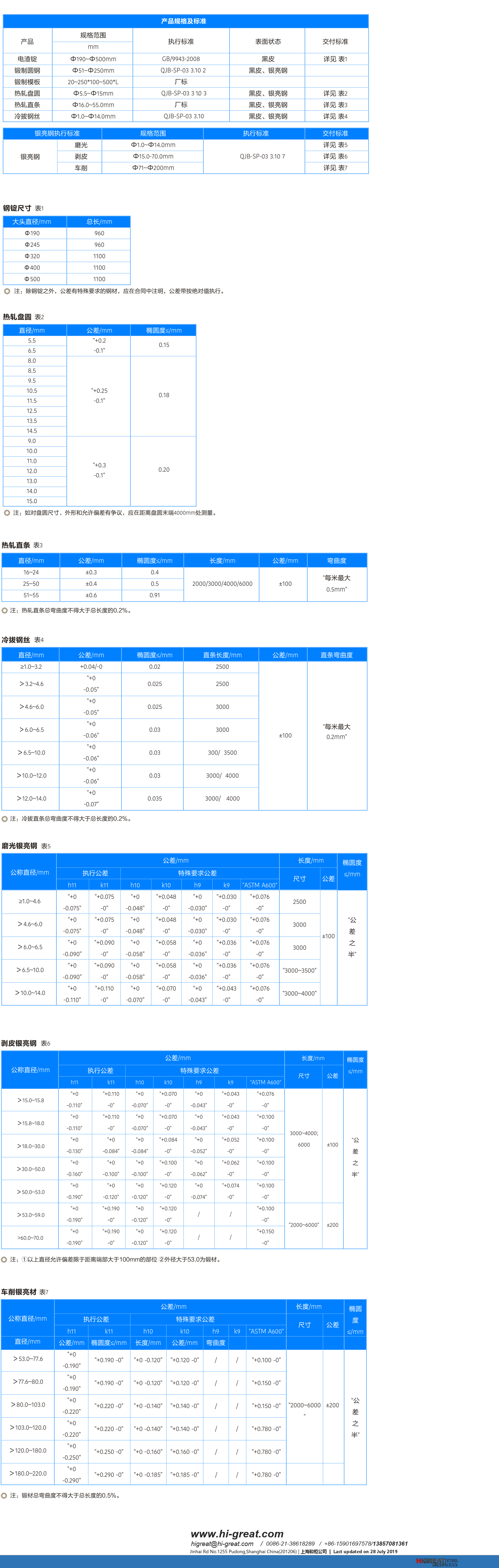

高速钢供货规格及公差附表 SIZE AND TOLERANCE

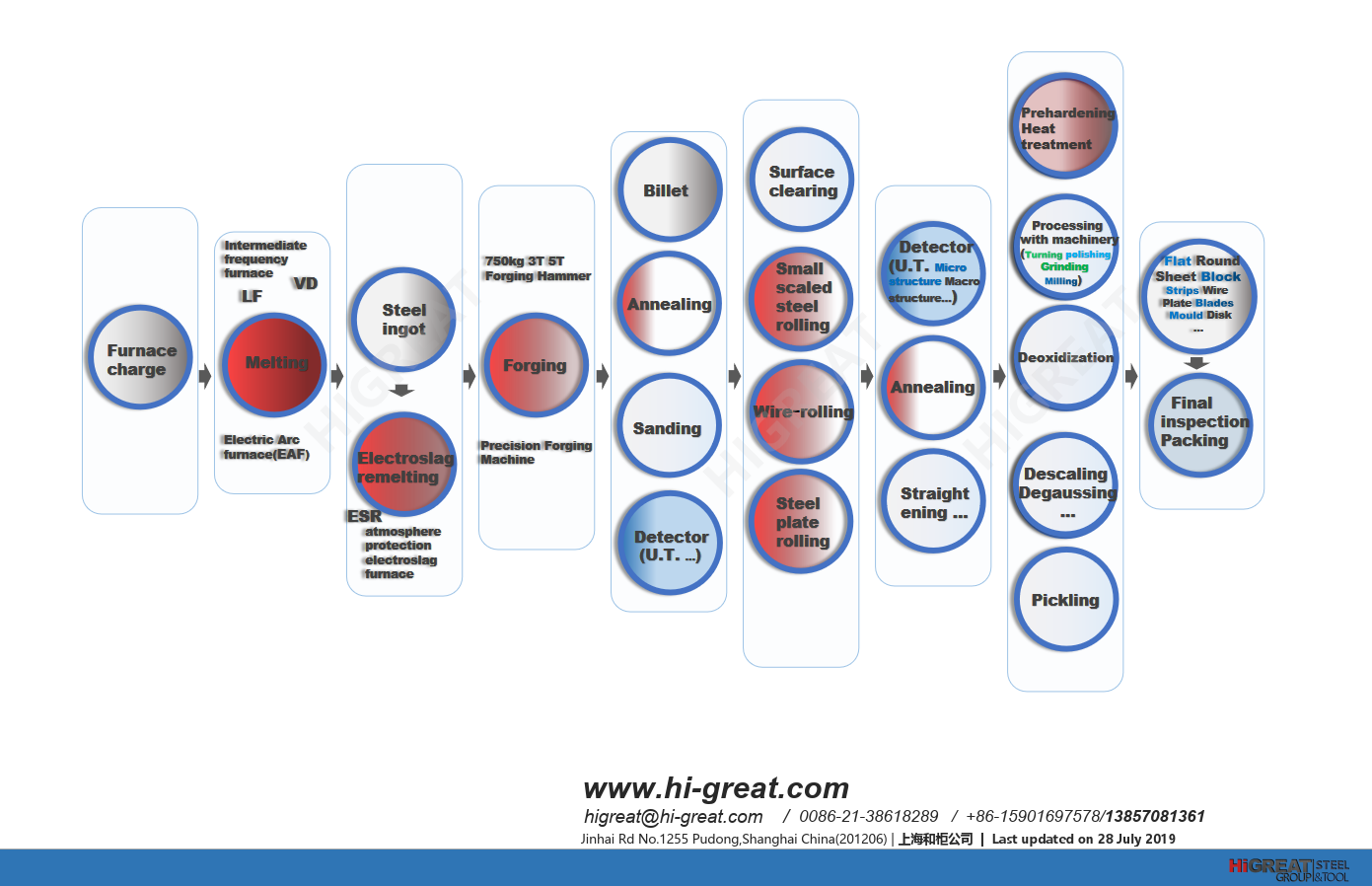

工艺线路图 PROCESS DIAGRAM

一流的设计,一流的制造设备、科学的工艺管控

源于材料研发设计领先精神,其工艺所用的主要生产设备均从美国、德国、日本等国家引进,与世界最先进水平保持同步,独特的精炼工艺,高于国家标准的工艺要求,为企业生产出高纯度、高质量的产品提供了坚实的保证。

对每一个生产工艺环节的科学管控,是HIGREAT卓越品质体系的重要一环。

工艺标准的发放和回收:质量部文控中心负责发放有效文件、回收作废文件;

工艺的执行:各工序按工艺要求生产和加工产品;

工艺执行验证:质检员严格按照工艺标准,对生产过程及产成品进行检查和检验;

工艺纪律的监督:质量部对工艺纪律状态进行实时监控;技术研发部针对工艺纪律的执行情况,每月进行不定期抽查。

If you are interested in our products,please send email to us to get more information:higreat@higreat.com

Marketing Network Map